14

2025-01

How to effectively perform boiler furnace maintenance and ensure power safety

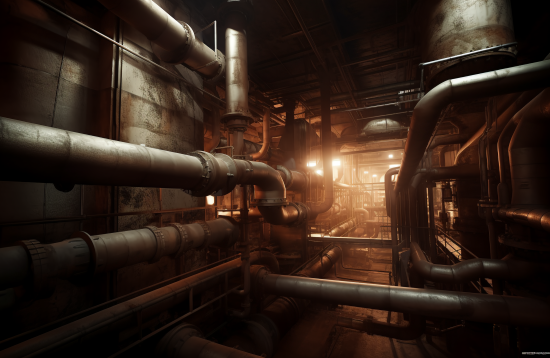

How to effectively perform boiler furnace maintenance and ensure power safety. In the power industry, boilers are undoubtedly one of the core equipment, and the boiler furnace is the key to ensuring its efficient and safe operation. Imagine that the boiler furnace is like the heart of the power system. If the heart has a problem, the entire system may face a crisis. Therefore, boiler furnace maintenance is particularly important. So, how to effectively perform boiler furnace maintenance to ensure power safety? Today, let's talk about this topic. The basic structure and working principle of the boiler furnace. First, let's understand the boiler furnace. It is mainly composed of furnace walls, furnace top, and furnace bottom, and is usually built with refractory materials to withstand high temperatures and high pressures. Under the influence of high-temperature gases generated by fuel combustion, the temperature inside the furnace will be extremely high. Imagine a high-temperature oven, every detail in the furnace can affect the final baking effect, and so is the boiler. If there is a problem with the furnace, such as carbon deposits or cracks, the performance of the boiler will be affected. The necessity of boiler furnace inspection. It is better to say that boiler furnace maintenance is a responsibility than a task. The performance of the boiler furnace directly affects the safe and stable supply of electricity. If regular maintenance is not performed, it may lead to equipment failure, even

2025-01-14

08

2025-01

Ensuring Safety in Thermal Power Plants: The Application of In-Furnace Inspection Lifting Platforms In the daily operation of thermal power plants, equipment safety and stability are paramount. Imagine working at heights without reliable safety measures – wouldn't you feel uneasy? Just as we need safeguards in our lives, thermal power plants require efficient and safe tools for in-furnace maintenance. This is where in-furnace inspection lifting platforms become indispensable "safety nets." Basic Concept of In-Furnace Inspection Lifting Platforms As the name suggests, in-furnace inspection lifting platforms are devices that provide lifting support for in-furnace maintenance in thermal power plants. Their design enables maintenance personnel to safely and conveniently perform equipment inspection and maintenance in high-temperature, high-pressure environments. Imagine maintenance personnel as if they were walking on air; with this platform, they can easily complete various complex tasks. Why Choose In-Furnace Inspection Lifting Platforms? First and foremost, safety is our primary concern. In-furnace inspection lifting platforms utilize robust materials and structural designs capable of withstanding significant weight, ensuring the safety of maintenance personnel during high-altitude operations. Furthermore, the platform's design also takes into account potential hazards during maintenance, such as flames and smoke, providing protection and...

2025-01-08

02

2025-01

Safety Guide for the Use of the Furnace Inspection Lifting Platform

Safety Guidelines for Using In-Furnace Inspection Lifting PlatformsIn many industrial fields, especially in metallurgy and chemical industries, in-furnace inspection lifting platforms play an extremely important role. They not only improve the efficiency of inspections but also ensure the safety of workers during high-altitude operations. However, the use of any equipment involves potential risks, especially in high-temperature environments or confined spaces. Therefore, understanding the safety guidelines for using in-furnace inspection lifting platforms is essential for every worker.I. Understanding the Structure of the In-Furnace Inspection Lifting PlatformFirst, we need to understand the structural characteristics of the in-furnace inspection lifting platform. It usually consists of a platform, a lifting device, a support structure, and a control system. Different lifting platforms may differ in design, but the vast majority have strong load-bearing capacity and easy operation. Imagine how dangerous the entire work would be without a stable foundation! Therefore, understanding each component of the equipment and ensuring that they are all in good working order is the first step in safe use.II. Conducting Equipment InspectionBefore using the in-furnace inspection lifting platform, a comprehensive equipment inspection must be carried out. This includes checking the stability of the lifting device, the load-bearing capacity of the platform, and the firmness of the support structure. We can

2025-01-02

27

2024-12

The Secret to Improving Power Grid Maintenance Efficiency: In-Furnace Maintenance Lifting Platform

The Secret to Improving Power Grid Maintenance Efficiency: In-furnace Maintenance Lifting Platforms In the modern power industry, efficiency is the goal of every enterprise. In the maintenance of various equipment, how to improve maintenance efficiency has become an important issue. Imagine if there were a tool that could allow you to complete work that would normally take hours in just minutes. That is the charm of the "in-furnace maintenance lifting platform". What is an in-furnace maintenance lifting platform? An in-furnace maintenance lifting platform is a device specifically designed for the power industry, mainly used for maintenance operations in high-temperature furnaces. It can move freely in confined spaces and adjust its lifting height as needed, allowing maintenance personnel to perform maintenance work more conveniently and safely. Doesn't it sound amazing? Imagine power equipment maintenance technicians having to climb up and down, bending over and hunching their backs—a real challenge of physical strength and endurance. With an in-furnace maintenance lifting platform, all these difficulties can be easily overcome. You can comfortably complete various maintenance tasks in a comfortable posture—a truly user-friendly design! Advantages of In-furnace Maintenance Lifting Platforms 1. **Improved Safety** When working in high-temperature furnaces, safety is always the top priority. Traditional

2024-12-27

21

2024-12

Why is choosing an in-furnace maintenance lifting platform a smart choice for the power industry?

Why is choosing an in-furnace maintenance lifting platform a wise choice for the power industry? In the power industry, safety and efficiency are paramount. During equipment maintenance, especially in-furnace maintenance, choosing the right tools and equipment is particularly important. In-furnace maintenance lifting platforms, as a type of professional maintenance equipment, are gradually becoming a popular choice in the power industry. Today, let's talk about why choosing an in-furnace maintenance lifting platform is a wise decision. Enhancing Safety First, we must mention safety. In the power industry, safety always comes first. Traditional maintenance methods often require workers to climb heights or work in confined spaces, which not only increases the risk of accidents but can also lead to equipment damage. The emergence of in-furnace maintenance lifting platforms solves this problem. Imagine, without an in-furnace maintenance lifting platform, workers might have to rely on unstable ladders or scaffolding. Is such a work environment reassuring? Of course not! In-furnace maintenance lifting platforms provide a stable and safe work platform, allowing workers to operate without worrying about the risk of falling, ensuring the safety of maintenance work. Improving Work Efficiency Next, let's talk about efficiency

2024-12-21

15

2024-12

Maintenance and maintenance techniques for in-furnace inspection lifting platforms

Maintenance and Maintenance Tips for In-Furnace Inspection Lifting Platforms In industrial production, in-furnace inspection lifting platforms are indispensable equipment. It not only improves the efficiency of inspection but also ensures the safety of maintenance personnel. However, many people often neglect the maintenance and upkeep of the platform after use, which is a big mistake! Today, I'll talk to you about the maintenance and maintenance tips for in-furnace inspection lifting platforms to help you extend the service life of the equipment. Understanding the Importance of In-Furnace Inspection Lifting Platforms First of all, it must be understood that the in-furnace inspection lifting platform is not a simple tool, but a key piece of equipment that ensures safety and efficiency. Imagine how many safety hazards maintenance personnel would face working at heights without a reliable platform? Therefore, the maintenance and upkeep of this equipment is particularly important. Daily Inspection, Cannot Be Overlooked Daily inspection is the first step in maintaining the in-furnace inspection lifting platform. You can perform inspections at regular intervals every day to ensure that all components are operating normally. For example, check if the lifting platform's cables are worn, if there are oil leaks in the hydraulic system, etc. Why check every day? Because many problems often arise inadvertently, like a small stone in a river, which over time can lead to the collapse of a dam. Regular cleaning, maintenance

2024-12-15

09

2024-12

How to choose a highly efficient in-furnace maintenance lifting platform?

How to choose a highly efficient in-furnace maintenance lifting platform? In industrial production, the use frequency of in-furnace maintenance lifting platforms is increasing. Have you ever wondered how to choose a highly efficient in-furnace maintenance lifting platform? If you are confused about this problem, let's discuss it together! ## Understanding the use of in-furnace maintenance lifting platforms First of all, we need to understand what an in-furnace maintenance lifting platform is. Simply put, it is a lifting device used for maintenance work in the furnace. Imagine, without such a platform, what kind of difficulties would maintenance workers face? High-altitude work is not only risky, but also extremely time-consuming. Through the in-furnace maintenance lifting platform, workers can safely and conveniently enter the furnace to carry out necessary inspections and repairs. ## Assessing your needs The first step in purchasing an in-furnace maintenance lifting platform is to assess your actual needs. You need to consider several key factors: 1. **Load-bearing capacity**: The load-bearing capacity of the platform you need can affect safety and efficiency. If your maintenance team has many people, or needs to move heavy tools, then choosing a high-load-bearing platform is particularly important. 2. **Lifting height**: Different furnaces have different heights, you need to choose according to your actual situation

2024-12-09

Over thirty years of industry experience

Our Products

Contact Us

No.10 Xingchen Road, Jintan District, Changzhou City, Jiangsu Province, China

Follow Us

Sweep the code to follow